Service

+48 794-581-260

info@smstage.co.uk

SpeedMobileStage designs and builds its mobile stages to work for many years.

But in the future you may need our help.

That’s why we have a well-stocked spare parts in our warehouse. 90% of parts to our mobile stages have at our place, which significantly shortens the time of delivery. For your convenience, we have created PARTS CATALOG of our stages. Catalogues are for download in the section „Questions and Answers” below.

We provide service and inspection by the „PROTECT SERVICE”. The program is a series of periodic, voluntary control tests of your stage. The service program is designed to determine the overall security level of mobile stage. More about the program below.

OPERATION – Questions and Answers

Our trailers must be tested at vehicle inspection station. The first technical inspection – MOT is carried out 3 years from the initial registration, each succeeding every year. . Technical inspection will cost up to 50 euros.

If you move the decimal point 2 places to the left, you get a score of 3.0. This value corresponds to the same pressure expressed in bars. So manometer (pressure gauge) can show no more than 3.0 bar.

If you move the decimal point 2 places to the left, you get a score of 3.0. This value corresponds to the same pressure expressed in bars. So manometer (pressure gauge) can show no more than 3.0 bar.

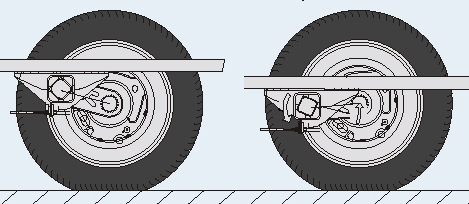

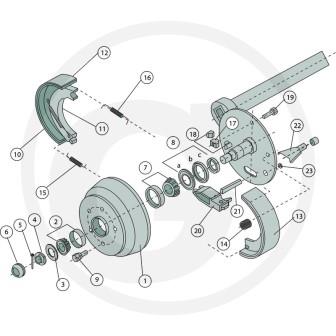

To adjust the brakes you need to spread out drums, evaluate their wear, replace the defective parts but above all you have to grease the mechanism and do regulation of clearance. This applies to trailers with known mileage or age.

Next thing to do is raise the trailer to a point when wheels rotate and adjust the spacing of the jaws from the drum (depending on the manufacturer toothed ring inside or the adjustment screw on the side of the chassis). At the beginning dismantle adjustable jaws to lock the wheel then loosen until the wheel starts to turn freely, however, friction of jaws and the drum should be slightly audible. We do the same with the other side. NOTE. When doing regulation revolve the wheel forward in the direction of travel.Then we adjust the potential difference in the braking force of the wheels. The easiest way: wheels in the air, apply the parking brake slightly and check that the wheels rotate with equal resistance. If you still need regulation pull up the screws slightly on the of the weaker side or loosen on the stronger. This treatment is not always necessary because Knott implemented as a standard brake with automatic adjustment ANS.

Then we pull up links by pulling rod not to have a large clearance (initially) on a drawbar connecting links of the pull rod. Please check after the regulation that the wheels are rotating freely, if not, then it’s been pulled too hard. As for the regulation of the brake when you are driving it is best to set it during the road test. Find a piece of straight rarely used road and try using brakes. We are trying adjust the tension of the tie rods to a point when wheels of the trailer are locking only when we are hard braking.

Another more troublesome for a thief invention is a lock on the wheel. It is more difficult to install and store but something for something.

But in our opinion the most reliable is Auto Casco in a duet with secure car parking.

We propose to equip a repair kit for self-patching tarpaulin . While you’re away from the workshop you will be able in a very simple way save your time and money. The patch for self-sticking is a simple and popular tool that you should always have on hand when working with the stage.

The oil level in the tank (when the trailer is fully folded and the trailer is in horizontal position) should be visible above the max indicator or on the top corner of tank (depending on the tank model).

The solution to this problem is replacing damaged or worn gas springs that are supporting the platforms.

Pracujemy na komponentach: